Palm bay’s Premier Conveyor Service Provider

In a fast-paced industrial set, operational efficiency becomes non-negotiable. The Conveyor system failure means a halt on your production line, which costs you thousands in productivity. Studies show that unpredictable downtimes actually put manufacturers at an average of about $260,000 per hour; therefore, it goes without saying that a reliable conveyor system is essential for your business. Conveyor system smooth operations take priority in Palm Bay industries wherein our integrated conveyor services would keep your processes running smoothly, cutting downtime and assisting your businesses.

Why Conveyor System Maintenance Is Important for the Business

Conveyor systems form the backbone of many sectors, moving materials along assembly lines, distribution centers, and other industries.

Yet, they can get faulty unless they are often repaired and maintained. Failure to maintain conveyor systems can lead to breakdowns and continued maintenance. With proactive maintenance, you can avoid these interruptions in service and keep your business productive and profitable.

Industry research says every minute a conveyor is down; it costs an average of $700. In cases of unplanned breakdowns, if maintenance was not already scheduled at least once a month due to the conveyor being used every day, the costs can go up to $30,000 in a year.

Proper conveyor system maintenance assures continuous production, efficiency, workers' safety, and control costs. Consistent servicing leaves a guarantee against costly auto-repair and other operational losses.

How Professional Conveyor Services Can Boost Your Business

Collaborating with a reliable conveyor service provider in Palm Bay will provide your business with:

Decreased Downtime: Preventive maintenance establishes probable problem points before they develop into major failures, keeping operations running smoothly, avoiding breaches in service.

Cost-Effective: Scheduled inspections and repairs will reduce the emergency breakdown frequency and maintenance costs by 20%-30% on average.

Higher Safety Standards: Maintenance of conveyor systems reduces work-related injuries and guarantees adherence to occupational health and safety standards.

Longer Equipment Lifespan: Regular servicing helps your conveyor system last longer while at the same time guarding against economic losses usually linked with premature replacements.

Our Conveyor Services in Palm Bay

We offer an integrated conveyor service for all business needs in Palm Bay. These services include:

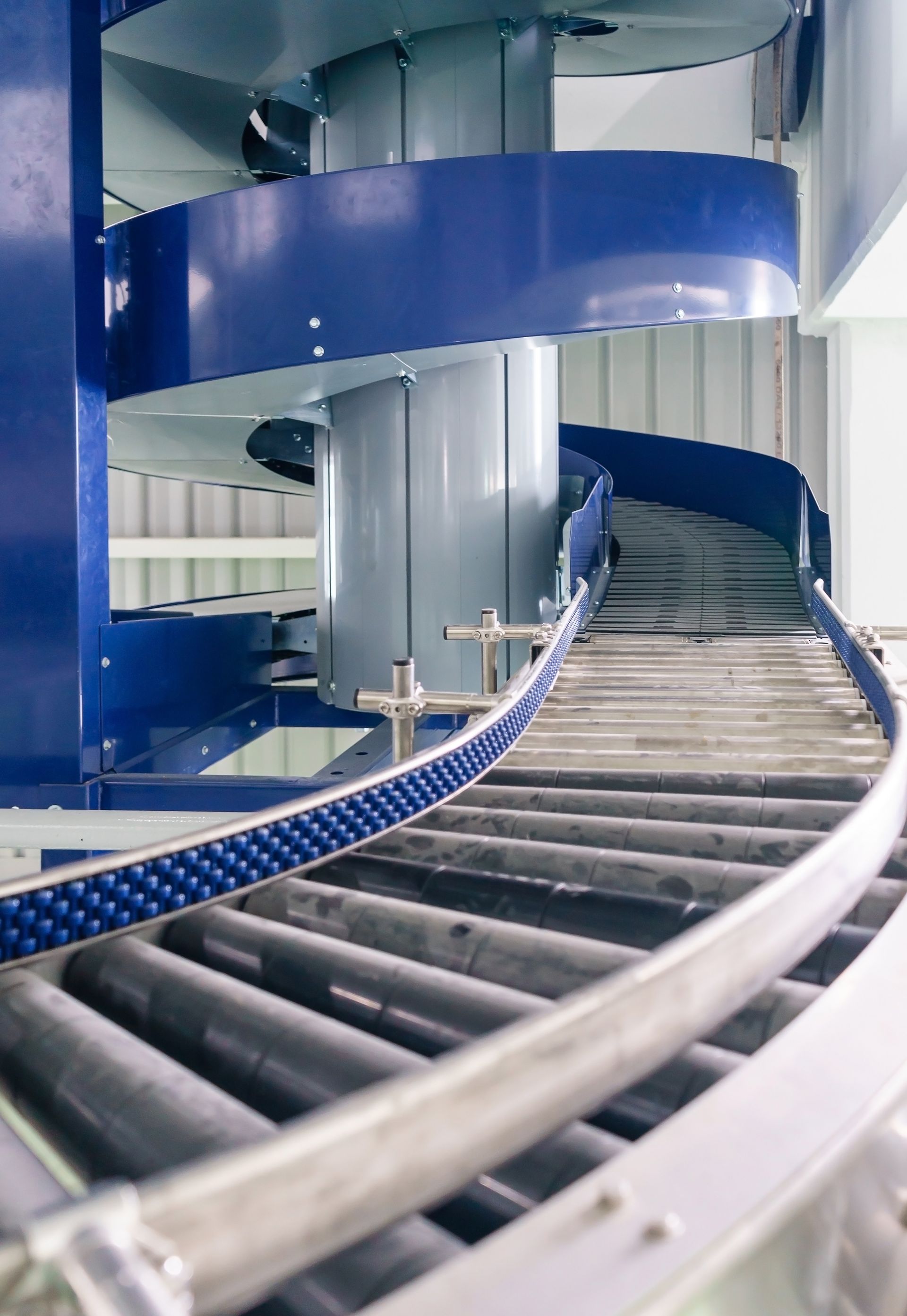

Conveyor Installation and System Design

Custom-built systems designed to meet the evolving operating needs of the facility as efficiently as possible. This will include everything from consultation and design to on-site installation.

Conveyor Belt Repair and Maintenance

Prompt and reliable repair facility for any conceivable issue, e.g., belt folding, tear, or any other conceivable mechanical breakdown. Preventive maintenance makes these units work continuously with less production disruption.

Conveyor System Upgrades

Upgraded older machines in order to reach higher production efficiency and adherence to changing industry guidelines. Proper analysis of your conveyor system is undertaken, with solutions offered at an economical price.

Emergency Conveyor Repair Services

We will respond to emergency failures 24/7 so that immediate, remedial actions can reduce downtime.

Custom Conveyor Solution

We provide custom conveyor systems for specialized applications, i.e., heavy-duty industrial conveyors, modular conveyor solutions, and custom installations.

Reasons for Choosing Conveyor Services in Palm Bay

Industrial Expertise: Offering superior conveyor service with years of hands-on experience tailored to your industries.

Customized Solutions: Design, install, and maintain conveyor systems for your business operations.

Response Promptly: Our emergency repair service is available round the clock so that you can resume your operations with minimal or no downtime.

Commitment to Quality: Only use the highest quality parts and latest techniques to guarantee long and dependable performance.

Customer Orientation: Our devoted team prioritizes customer satisfaction, communicated in a clear voice with constant support regarding the projects they are dealing with.

Our Process

Initial Consultation: We begin with a broad assessment of your conveyor needs, operational goals, and specifications for the system.

System Evaluation: Our team thoroughly inspects each work area to identify existing problems and any areas where operational efficiencies could be realized.

Action Plan: We create customized options based on your business needs to install, repair, and maintain the system.

Implementation: Our professional technicians will execute the service plan with a minimum of downtime or interference in your daily operation.

Ongoing Maintenance and Support: Planned programs will evaluate the system regularly to provide improvements to avoid problems down the road and to extend the life of your conveyor equipment.

Industries We Serve

We primarily deal with the industry segments that rely significantly on effective conveyor systems. These include:

Manufacturing: Conveyor solutions for smooth assembly lines and material application.

Distribution and Logistics: High-speed conveyors to assist in sorting, packing, and shipping operations.

Food and Beverage: Hygienic systems made for efficient product flow.

Pharmaceuticals: Precision systems for safe handling and compliance with strict industry requirements.

Automotive: Durable conveyor systems transmit significant, complex machinery components.

E-Commerce: High-delivery-rate systems for supporting rapid order delivery.

Take The Next Step For Conveyor Services In Palm Bay

A problem with a conveyor system should not bring an entire operation to a halt. A new conveyor system can be installed, routine maintenance can be undertaken or an urgent repair can be made. We have the expertise to do it rapidly and competently. Our team will be ready to assist you once you team up with a knowledgeable partner on how your conveyor systems can be safe and reliable.

Contact us today for a consultation on how our

specialized conveyor services in Palm Bay will protect your operations, lower downtime, and raise productivity.

Frequently Asked Questions

How often should conveyor systems be inspected?

Monthly routine testing of conveyor systems should become the norm for the future. More advanced testing should take place quarterly. Belts, motors, and rollers shall be inspected more frequently with critical components to curb any further wear and/or misalignment.

What are the typical problems associated with conveyor belts?

Several problems are known: belt offsets, motor failures, bad beads, and materials buildup. Whenever these problems can be identified early enough to be addressed, it will save the plant extra repair costs.

Do you mean that you can design conveyor systems for my industry?

Yes, we do custom design and installation, suited to the unique requirements of individual industries, that we have practiced for years.

What will I do if my conveyor system goes down?

Call our 24/7 emergency service department. We will send trained technicians right away if you detect a problem, and their quick diagnosis will reduce downtime.

How is it time to replace my conveyor?

Indications that a changeover to newer models is in order are high levels of breakdown, declining production, and outdated technology. Our expert professionals will review your system against manufacturing needs and propose viable upgrades