Coral Springs’ Premier Conveyor Service Provider

The industry's modern, fast-paced world now thrives on conveyor systems' operational efficiency and reliability. Unexpected failures of a conveyor can be disastrous to production. Some studies have indicated that unplanned downtime could cost a company as much as $14,000 in lost opportunities for every minute. For the businesses in Coral Springs, ensuring that the conveyor systems are in tip-top shape is a priority and an absolute immediacy. Through high-volume manufacturing or fine sorting of materials, maintaining the conveyor system and avoiding interruptions is the key to enhanced productivity.

Importance of Conveyor System Maintenance

Conveyor systems are important in many industries and facilitate the smooth transport of materials and products. These systems complement the workloads, which means reduced manual labor and increased productivity.

These systems also break down if not maintained regularly, which can mean loss of production time and safety hazards. Routine supervision work on the conveyor will lengthen the equipment's lifespan and ensure safe usage by the workers, thus sparing the employer's finances.

Unplanned maintenance can cost companies as much as ten times more than planned preventive maintenance.

Implementing a

regular conveyor maintenance plan can reduce unplanned failures by 70%, thus saving companies tens of thousands of dollars a year. In sectors dependent on just-in-time manufacturing, delays can cause economy-wide ripple effects, missed deadlines, and dissatisfied customers.

Improving the Efficiency of the Business with Expert Conveyor Services

Professional conveyor services offer several benefits:

Reduced Downtime

Regularly scheduled maintenance can identify and deal with potential problems before they take root, allowing operations to continue. Systematic inspections have been shown to bring displays of up to 50 percent reduced downtime, guaranteeing a calibrated operation system in your business.

Savings in Repair Costs

Preventive maintenance will save on huge repairs and the indirect costs of emergency repairs. Studies have revealed that, with their soy practices, preventive maintenance cut the repair costs for participating companies' operations by as much as 18 percent.

Safety Assurance

Well-maintained systems significantly mitigate the risk of work-related accidents, ensuring a safe environment for employees. Faulty conveyor systems can cause injuries to employees, becoming a liability for the organization and exposing it to regulatory sanctions.

Increased Lifespan for Equipment

Regular service of conveyor systems prolongs the service life, ensuring your long-term investment. Worn-out

conveyor belt systems usually have a lifespan of more than 40% longer than those that would otherwise be poorly maintained.

Range of Services Available

These services can be availed by the industrial populace-We deal in a complete range of all conveyor services in Coral Springs, including:

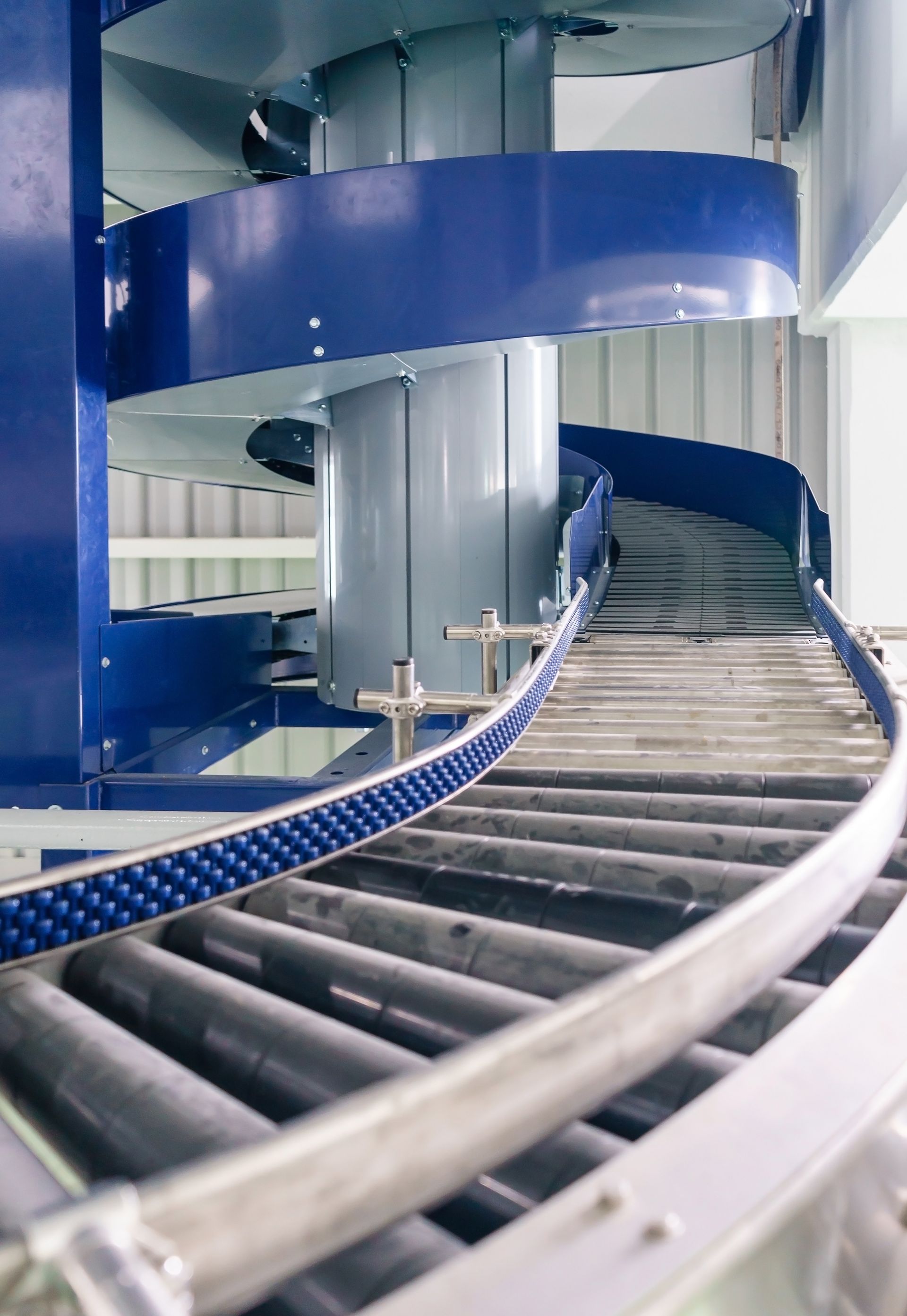

Conveyor Installation and Systems Design

This is how we fit into your plant requirements. Our engineers design systems around workflow efficiency required and adaptability to changing production demands.

Conveyor Belt Repairs and Regular Maintenance

We provides systematic service to ensure smooth operational flow. From belt tracking to motor deficiencies and wares, our technicians get down to the root of the problem immediately.

Conveyor System Upgrades

Upgrading older systems for enhanced performance and flexibility. We will upgrade the systems if they need to be updated with current standards.

Emergency Conveyor Repair

24/7, with emergency-call staff, for little or no interruption to your operations when repairs must be performed urgently.

Custom Conveyor Solutions

Able to provide integrated designs applicable to your industry needs- from modular conveyors to heavy-duty systems for extreme working conditions.

Why You Choose Our Conveyor Services in Coral Springs?

Knowledge and Experience: Our staff has years of experience and industry knowledge in working with conveyor systems in many industries.

One Solution Fits All: Each business and its requirement is unique, so we come to you with one solution that will fit your specific needs and deadline.

Quick Response: Our emergency service first fixes things, so you can always count on us and never have working machines down.

Promise of Quality: We use the best available materials and state-of-the-art technologies to provide some of the most consistent, long-term solutions.

Customer Satisfaction: Our customers have given us unchallenged trust based on our reliability, competence, and commitment to deliver beyond expectations.

Our Process

Initial Consultation: Understanding your specific needs and challenges. We will work with you in detail to draw in a workable scope of your conveyor system while determining improvements to be implemented.

System Assessment: Performing a thorough evaluation of the conveyor system management that must include tracking, operational motor efficiencies, and structural integrity.

Personalized Solutions: Formulate centuries that fit your operational goals. Providing a one-stop package of service from design to long-term maintenance.

Implementation: Total execution of the plan with minimum disturbance to your activities. Our proficient team ensures installation and repair, catering to speedily keep you aligned with the production schedule.

On-going support: In-depth monitoring and management by highly skilled technicians. We also provide service contracts with regular inspections, maintenance, and emergency services.

Industries We Work With

Manufacturing: High-volume manufacturing environments geared toward effective and efficient production processes.

Distribution and Warehousing: Systems designed for fast sorting and packaging.

Food and Beverage Processing: Systems conforming to accepted food and beverage safety operating practices as a contribution to profit maximization of productivity.

Automotive: Based on the movement of heavier materials and accurate delivery of line parts.

Pharmaceuticals: Highly expedited handling of sensitive materials and regulations.

E-commerce: Handling high-speed conveyor systems with quick order fill and shipment.

Get Started Today

Don't wait for something to break down. Please schedule a consultation today and learn how our servicing has helped many other businesses develop operating efficiency and safety.

Spending money on reliable conveyor services is a wise investment that helps prevent expensive shutdowns and inefficiencies for your business. Give us the chance to keep your operation running correctly and efficiently.

Frequently Asked Questions

Why is conveyor maintenance necessary regularly?

Regular maintenance prevents unexpected breakdowns, saves downtime, and increases the life of your equipment. It also ensures safety compliance, safeguards your employees, and reduces liability exposure.

How frequently should conveyor systems be inspected?

Inspecting heavily used systems at least monthly, with more frequent inspections, is advisable. Motors, belts, and rollers are high-risk components to be closely examined to identify the earliest evidence of wear.

What are some typical warning signs that indicate a conveyor belt needs repair?

Signs are unusual noises, offset belts, visible wear and tear, and decreased operating speed. Correcting these symptoms earlier will avoid more serious issues and expenses caused by downtime.

Do you custom-design conveyor systems for specific industries?

Yes, we are experts in designing and installing conveyor systems tailored to different industries' specific needs. Our solutions are production volume, material, and industry standard-based.

Do you offer emergency repair services?

Yes, we're here 24/7 to get emergency repairs done so that operations can continue with reduced downtime. We know how important conveyor systems are and prioritize getting quick, effective repairs done.